For people who use binoculars, you must have come through the phrase “Extra-Low Dispersion ED Glass” mostly known as ED glass. If you have never understood what it means, today is your luck. I am going to give you every important detail on what you should know about an ED glass in regard to your binoculars.

Extra low dispersion glass is widely used in the best optics applications and more so in areas where accuracy and also the clarity of vision plays a key role. Due to its capacity and importance in optic applications, ED glass is usually used on binoculars, high-end camera lenses, scopes, and rangefinders among many other devices that should provide high-end image quality.

How Optics Work? What is Dispersion and Aberration?

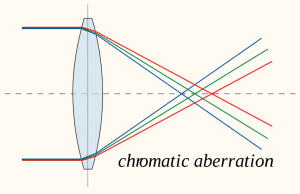

When light travels through glass or lens its phase velocity changes and breaks into its component colors. A good example that will make this concept simpler is the prism concept. When a light ray hits on a prism, it splits into different colors. These many color waves are usually produced depending on their particular frequencies.

This type of separation of light waves as they pass through an optical glass is what we refer to as dispersion or chromatic aberration (CA).

Another type of dispersion is called spherical aberration (SA). It is the result of lens curvature, not the result of prism effect. When light travels from a distant object through the lens, it can’t accurately be focused toward the focal point or retina. As a result, the observer sees blurry halos around the image.

Why the Extra low dispersion (ED) Glass?

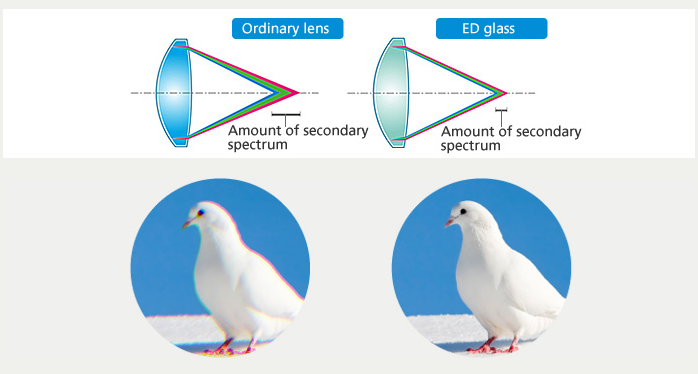

The reason why we need an ED glass when it comes to optics has everything to do with chromatic and spherical aberration. When viewing through normal optics, chromatic aberration produces an image with rainbow effects, or the subject being viewed has a noticeable colored edge -blue, purple, even yellow. This chromatic aberration is most obvious when viewing high contrast objects.

Now, this is where an ED glass steps in to help and minimize any distortion caused by chromatic or spherical aberration. ED glass has been improving with the latest technology that minimizes those image distortion. ED glass is sometimes referred to as HD glass. You may hear some manufacturers use the term fluorite as well. Basically, binoculars or other scopes that have ED, HD or fluorite glass have one or two extra glass elements in there to minimize these chromatic aberrations.

How Is Extra Low Dispersion (ED) Glass Made?

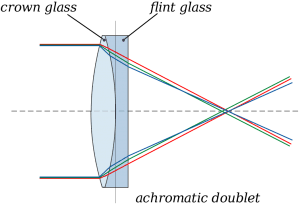

Traditionally ED glasses were made by merging two main glass elements (crown glass and flint glass) into one unit called an achromatic doublet. The reason two glass elements were merged was to enable them to cancel out in case one element had higher dispersion characteristics than the other. In some cases, manufacturers would coat lenses with any other substances that were designed to produce much more similar effects. This type of ED glass made from achromatic doublet was a big step forward in reducing chromatic aberration and hence producing sharper image quality.

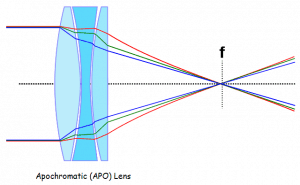

Another type of ED glass is apochromatic lens (APO) or apochromat which is more efficient in reducing chromatic aberration as well as spherical aberration. Thus binoculars that come with an apochromatic lens produce further improved quality images than the achromatic doublet can.

Apochromatic lens (APO) is made with three glass elements combining together.

Lens Materials

Traditionally ED glasses were produced by mixing fluorite based minerals. However, fluorite based ED glasses tend to fracture upon exposure to temperature fluctuation, if not manufactured to exacting standards. Even today the use of fluorite based minerals in ED glass is widespread. Nikon is considered a pioneer of the ED glass of modern-day. Canon also uses similar technology to make its premium calcium fluorite ED/HD lenses. Today zirconium dioxide, calcium fluoride, titanium dioxide, and other rare-earth elements are used to make these ED or HD glasses. The result of this high-end technology has minimized CA and SA to greater heights and given out sharper and brighter images for high-end optical gadgets too.

Examples of Low Dispersion ED Glass Binoculars

Today almost all brands’ flagship models use extra-low dispersion (ED) glass in order to give better color correction.

For example, Bushnell’s Legend L-Series and M-Series models; Celestron’s Granite models; Zeiss’s Terra ED models; Nikon’s Monarch 7 models – they all use ED glass.

Advantages of Using ED Glass in Optical Devices

When you look through a pair of normal binoculars at long distance, say a deer or something with antlers on it, you may see that color fringing. In that case, it’s hard to pick out the details of that antler or the spots on that deer. ED or HD glass binoculars give you that fine detail and sharpness when you look through the binoculars. ED glass binoculars are especially important if you go for long-range viewing especially out west. If it’s closer ranges the Midwest eastern United States where you only view a hundred yards or so then it’s not quite as critical to have that but Western hunting definitely.

ED glass is also much more efficient in terms of light transmission, which enables it for quicker focusing adjustment and brighter images in your viewfinder.

Since ED glass is designed to minimize the characteristics of CA inside optics devices it has to be very viable. One quality that guarantees an ED glass is its high resistant to temperature changes which adversely affected the capacity of previous lens variations in minimizing CA. Clearing the effects of CA in optic devices requires solutions that are based on finding the best types of glasses, lenses, and coatings that are pretty suitable in producing the right dispersion effects.

Modern glass fabrication techniques have taken huge strides into this. They employ materials that have been tested for precise quality and use computer control to even maintain furnace temperatures and enjoy consistent flows during cooling with the exact substrate mixing that gives a much more consistent result.